PTFE and PTFE compounds from the specialist

Our company, Heute+Comp. GmbH+Co in Radevormwald, can look back on a long company tradition. We have been involved in the processing of fluoroplastics since 1965. We produce semi-finished products such as tubes and solid rods as well as turned parts in-house. PTFE compounds from Heute+Comp. are produced by RAM extrusion or compression moulding and subsequent sintering.

Sintering is a process in which a moulded blank without a defined strength is sintered at a temperature above 360 °C. After heat treatment, controlled cooling takes place. After heat treatment, controlled cooling takes place. The semi-finished product then has the desired mechanical properties and can be machined.

We use the pressing and sintering process for semi-finished products with large diameters. It is primarily suitable for small and medium quantities. RAM extrusion is a process for the mass production of components and for the manufacture of rods and tubes.

The precise assembly of your turned parts is carried out on our modern CNC and cam-controlled machines. We supply you with seals, sliding and guide elements made of PTFE, PTFE compounds, PEEK, PCTFE, POM, PA and PE, for example.

A wide range of applications

We are your competent and flexible partner for prototypes, small series and large quantities. Our customers are at home in many industries:

- in chemical plant engineering

- in the automotive industry

- in hydraulics, electrical and medical technology

- in mechanical engineering

PTFE compounds – it’s all in the mix

PTFE is a material that is characterised by a range of positive chemical and mechanical properties. The possible applications for this plastic are wide-ranging.

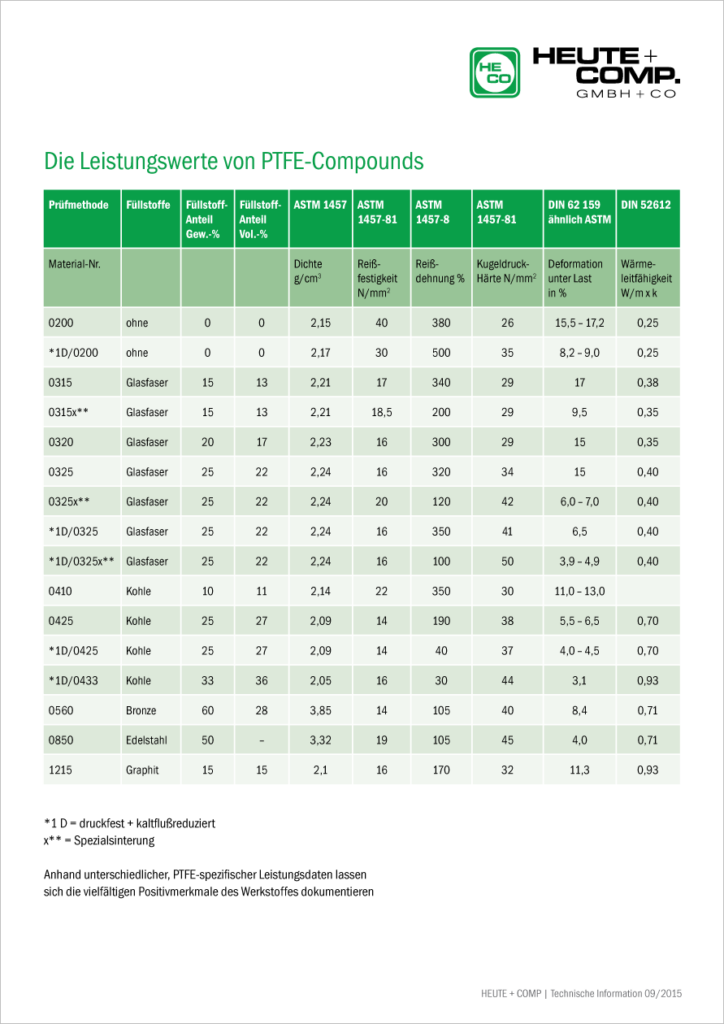

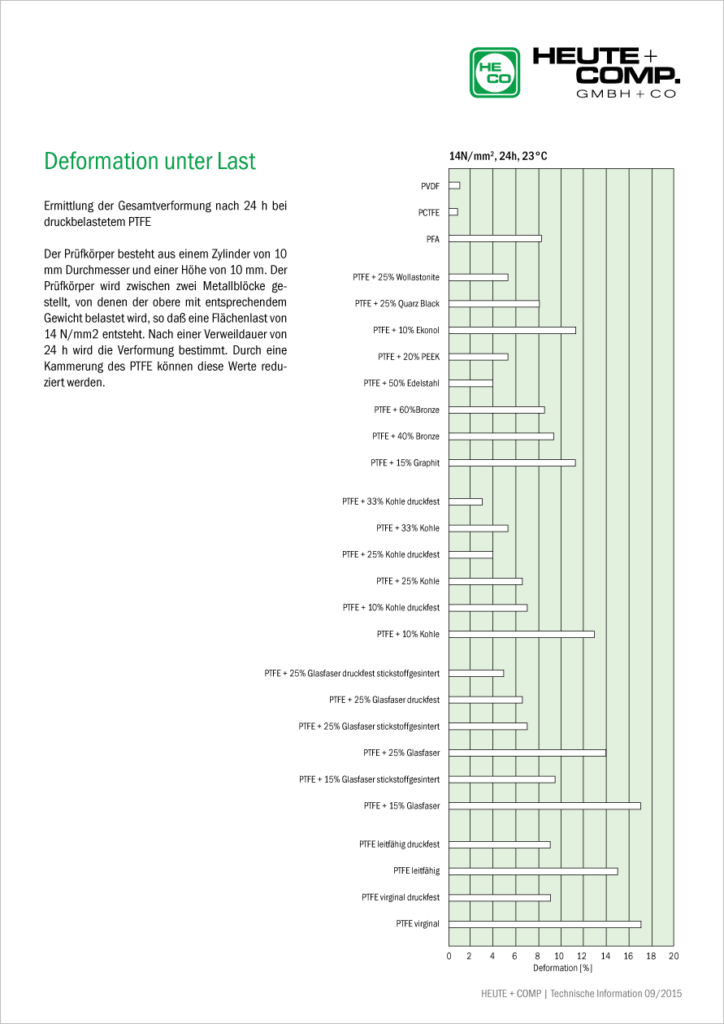

To produce PTFE compounds, PTFE is mixed with other materials (e.g. carbon, graphite, organic fillers, metal alloys, etc.) in order to vary various properties. This results in customised materials whose material properties are precisely tailored to the requirements.

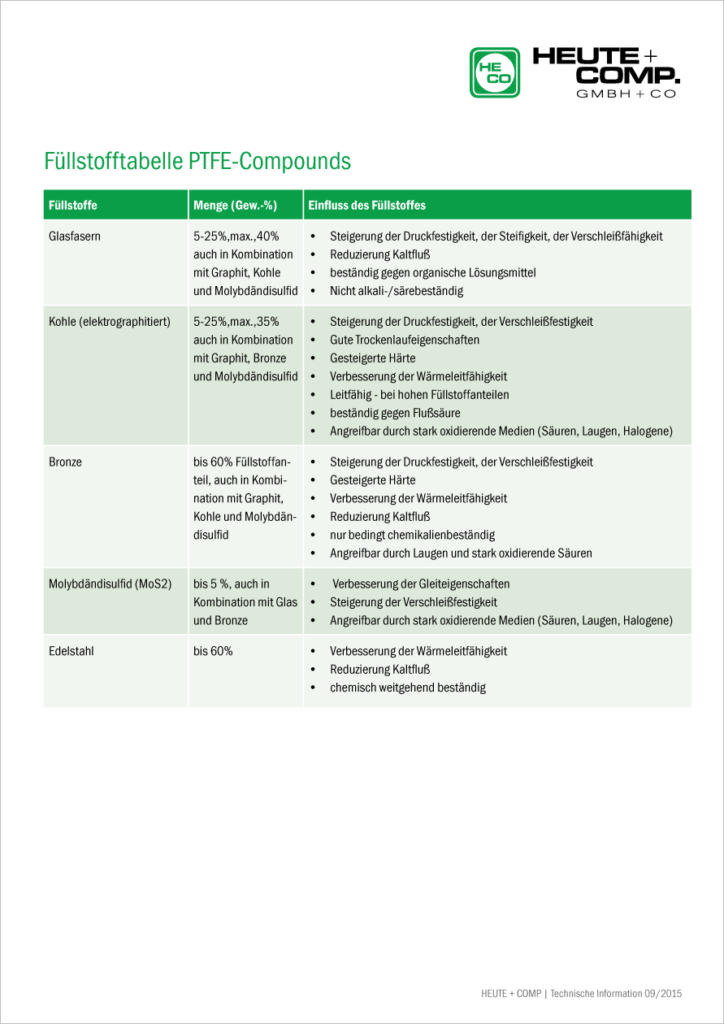

We combine PTFE with the following materials to create high-quality PTFE compounds:

- Glass fibres (increased compressive strength, rigidity and wear resistance; reduced cold flow; resistance to organic solvents; not alkali- and acid-resistant).

The glass fibre additive amounts to 5-25 percent. A maximum of 40 per cent may be contained in combination with carbon, graphite and molybdenum disulphite. - Electrographitised carbon (improved compressive strength, wear resistance, thermal conductivity and hardness; good dry-running properties; resistant to hydrofluoric acid; conductive with a high filler content; can be attacked by oxidising acids, alkalis and halogens).

The proportion of electrographitised carbon can be 5-25 percent. A maximum of 35 per cent is permissible in combination with graphite, bronze and molybdenum disulphite. - Bronze (increased compressive strength, wear resistance and hardness; improved thermal conductivity; reduced cold flow; limited resistance to chemicals, is attacked by alkalis and strongly oxidising acids).

Bronze, optionally in combination with graphite, carbon and molybdenum disulphite, may contain up to 60 per cent. - Molybdenum disulphide (improves sliding properties and wear resistance; can be attacked by acids, alkalis and halogens).

The proportion is 5 per cent; combinations with glass and bronze are possible. - Stainless steel (extensive chemical resistance; reduced cold flow; improved thermal conductivity).

The filler content may be up to 60 per cent.

PTFE compounds are the preferred choice of material for threaded sealing rings

PTFE compounds guarantee a secure seal. Hemp and PTFE tape are not necessary. We manufacture our thread sealing rings from a special brown compound. The components can be easily joined together, reassembled and rotated for correction. Thread sealing rings made of PTFE compound are used millions of times and have proven their worth. We have KTW and WRC approval.

Our quality assurance team ensures the consistently high quality of our products. We create test specimens from the purchased raw materials, which have to pass stringent tests. We test the mechanical values such as elongation at break, tensile strength and ball indentation hardness. Only flawless materials are used for further processing. Production is subject to continuous testing with recording of SPC characteristics. Process reliability is guaranteed and verifiable.

Our quality management is certified in accordance with DIN EN ISO 9001:2015, IATF 16949:2016 and DIN EN ISO 14001:2016.