PTFE – versatile material with important properties

PTFE (also known by the trade names Teflon, Hostaflon or Fluon) is characterised by a number of extremely useful properties for a wide range of production and processing applications:

- Almost universal chemical resistance

- High temperature resistance

- Excellent sliding properties

- Very good insulation behaviour

- (Almost) completely resistant to unwanted water absorption

PTFE is the high-performance all-rounder for industry

Globally based and active clients and customers from industries such as…

- Automotive

- Chemistry

- Electrical engineering

- Mechanical engineering

- Medical technology

- Pharmacy

- Food

- and many other sectors of the industry

…rely on turned parts and semi-finished products from HEUTE+COMP. All products “Made in Radevormwald” are characterised by high quality. At HEUTE+COMP., new incoming raw materials undergo strict quality testing as part of the production of test specimens. This includes, for example, a test of ball pressure hardness and tensile strength.

From the Specialist and your Trusted Industry Partnert

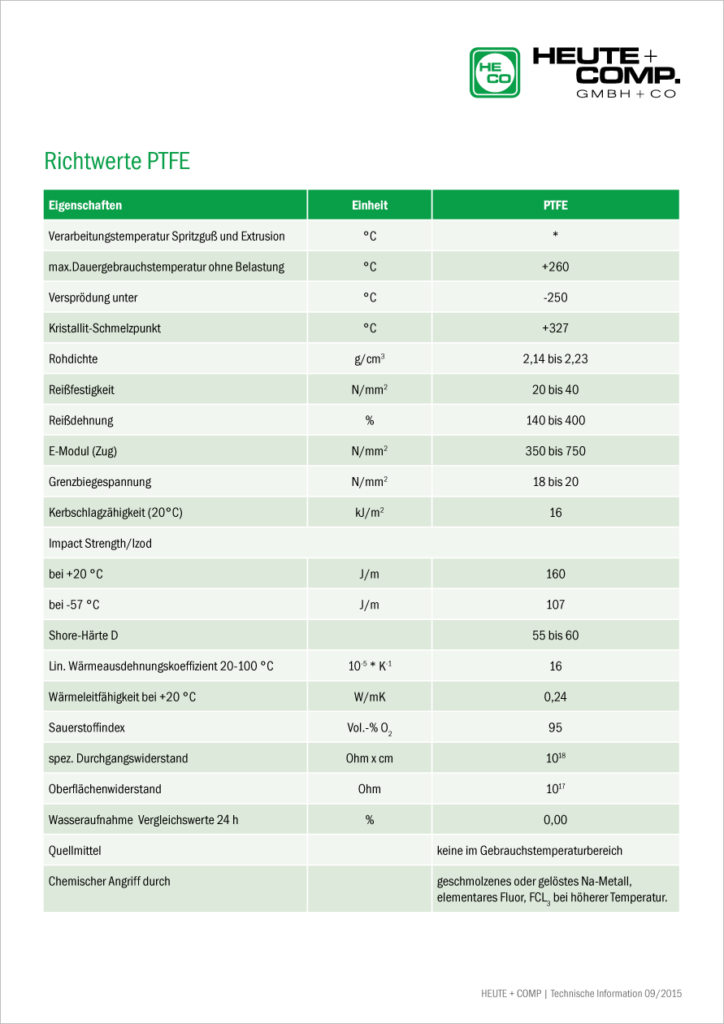

Thanks to its versatile advantages and properties, PTFE can be individually tailored to effortlessly meet a wide range of industrial requirements. The exceptionally strong bonds between the fluorine and carbon atoms in its molecular chain mean that only a few substances—elemental fluorine among them—are capable of attacking the plastic. Due to its high temperature resistance, PTFE can also be used continuously at operating temperatures ranging from -250 °C to +260 °C (without mechanical stress). The coefficients of friction for PTFE are also nearly identical in both static and dynamic applications.

PTFE Advantages Beyond the Basics – Performance You Can Rely On

Service and advice for customers, the highest quality standards in development and production, plus a high-performance and versatile material: PTFE solutions from HEUTE+COMP. also help your company to make production and/or processing safer, more efficient and better.

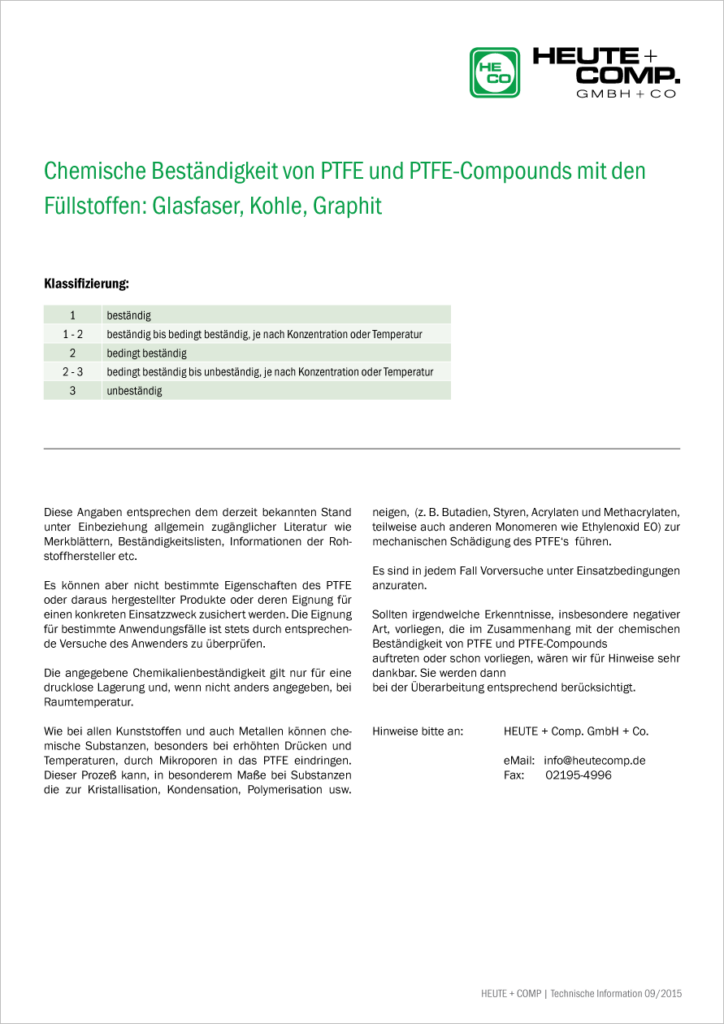

A list of the media resistance of PTFE and PTFE compounds can be found here.

The dreaded “stick-slip effect”, which increases the breakaway torque when the system starts up, does not occur.

Side effect: PTFE construction parts are easy to clean because nothing can stick to them.

PTFE has very good insulation behaviour: The insulation performance of PTFE is superior to most other plastics, especially in the high-frequency range (including ultrasound). The specific volume resistance of pure PTFE is 10¹⁸ ohm·cm.

In addition, the term “water absorption”, which is extremely feared in many industrial applications, is almost a foreign word for polytetrafluoroethylene. Under test conditions, water absorption is less than 0.01%.

Some mechanical properties can be found in this table.

PTFE Compounds: When great things can still be improved

Although PTFE is already highly versatile, the material can be further customized to meet specific application needs through the addition of fillers—especially when pure (virgin) polytetrafluoroethylene does not quite meet your high standards. This is achieved using various compounds, which may include fillers such as bronze, stainless steel, glass fibers, carbon (graphite), or molybdenum disulfide. These fillers—either individually or in tailored combinations—can significantly enhance PTFE’s performance characteristics. For example, pressure and wear resistance, hardness, and thermal conductivity can all be improved considerably. Further information can be found here.

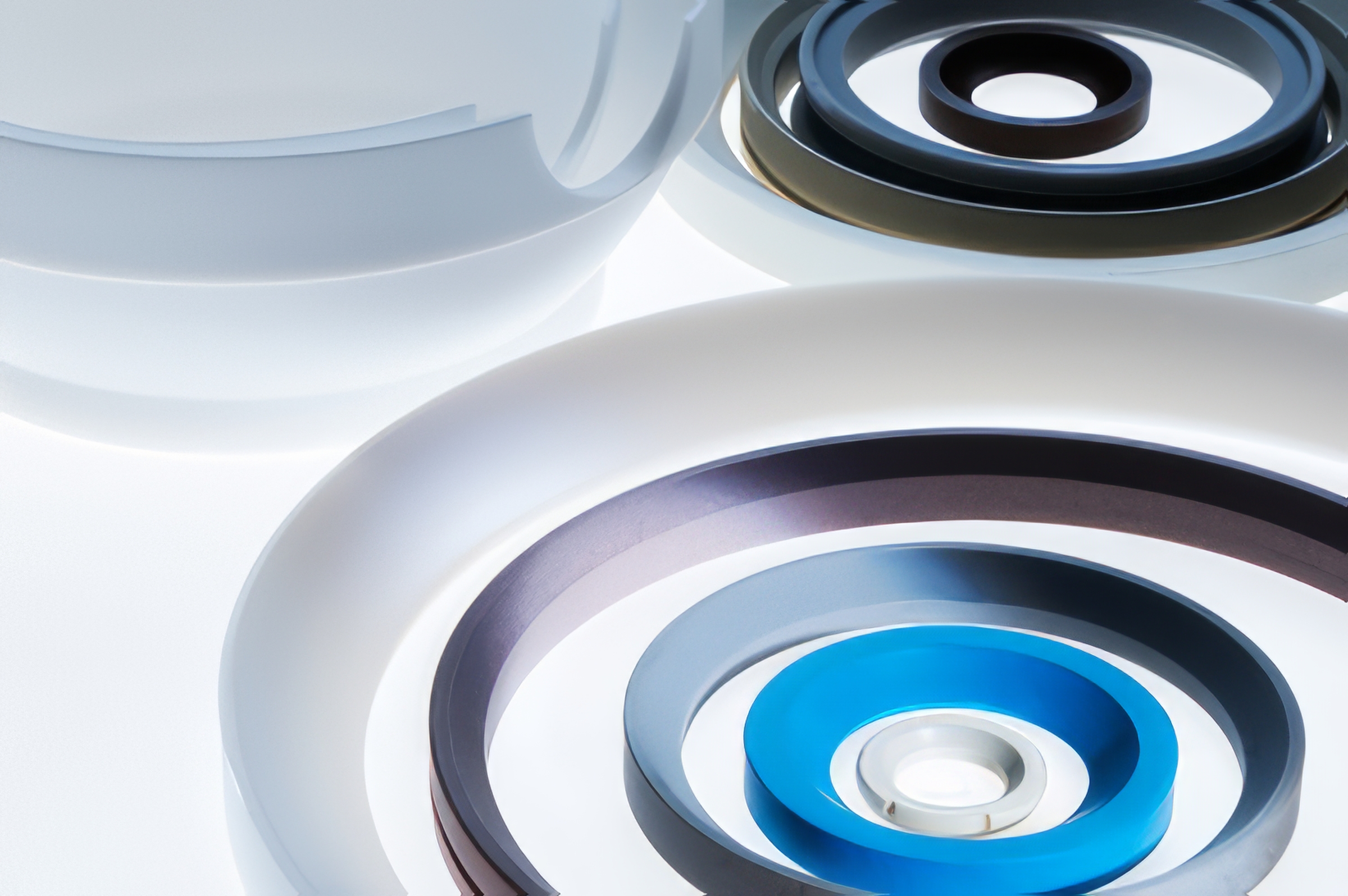

PTFE Turned Parts: Precision in Motion

Rotating parts often play a critical role in various products—from tiny micro-components used in medical technology or watchmaking to larger long-turned parts used in mechanical engineering. Using machining technology, plastics can be produced with exceptional precision—thanks in large part to today’s advanced CNC systems.

At HEUTE+COMP, state-of-the-art, high-quality CNC machines manufacture PTFE turned parts with maximum reliability, precision, and durability—custom-made exactly to your specifications. The material quality of this high-performance plastic can also be further optimized through compounding, even for turned components.

PTFE semi-finished products – High-quality basis for Precision Manufacturing

When it comes to selecting the right semi-finished products, HEUTE+COMP offers expert consultation—especially in determining which fillers are best suited for your product’s intended application. These semi-finished goods, which serve as the perfect starting point for future custom-made components, offer a wide range of applications, whether in the form of blocks, sheets, profiles, or tubes.

They are particularly well suited for the production of PTFE seals. In this area, we primarily use glass and carbon as performance-enhancing fillers. Strict monitoring of all critical process steps forms the foundation of our high standards in both material quality and manufacturing.

These are just a few examples of how HEUTE+COMP., an innovative company with a long tradition, can optimise production, processing and other work processes as a partner to industry. Simply get in touch and let us show you how your company can benefit from this superlative plastic. Use our contact form, send an e-mail to info@heutecomp.de or give us a call on +49 2195 – 676-01.