No half measures - only quality semi-finished products.

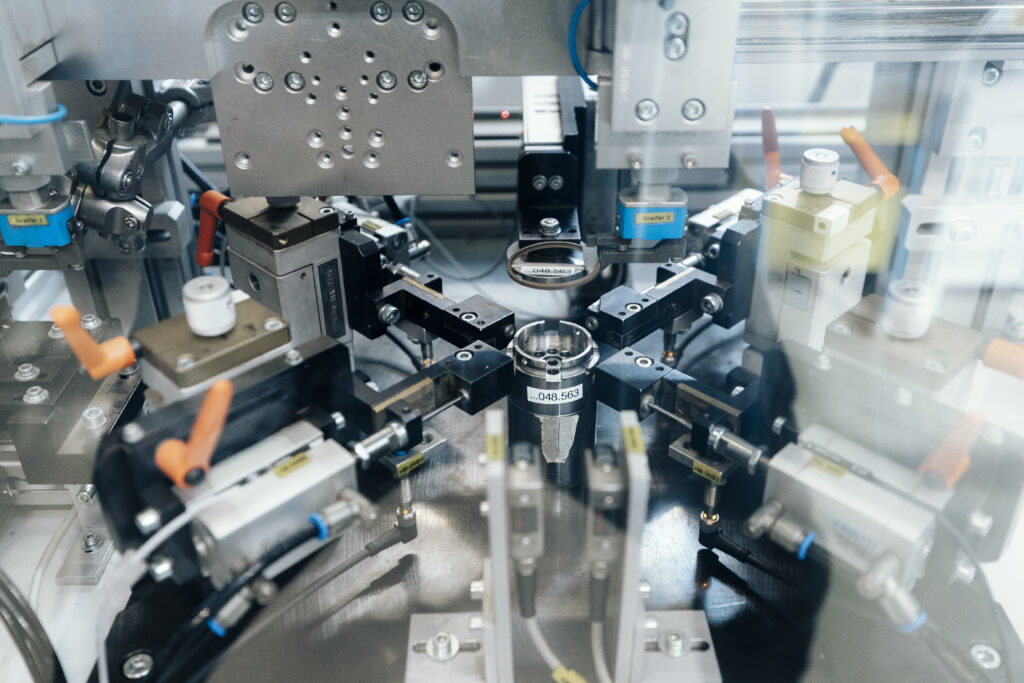

At HEUTE+COMP, we operate more than 100 cutting-edge production systems in a continuous 3-shift cycle — manufacturing precision-engineered components from nearly all high-performance plastics.

To maintain our outstanding quality standards, we produce semi-finished goods such as tubes and solid rods in-house. We rely on premium materials like PTFE, PFA, and FEP, which are processed using advanced techniques such as RAM extrusion and compression molding, followed by sintering — all tailored to the specific properties of each raw material.

Short production times, long design freedom.

The final transformation into high-precision, durable end products takes place in our modern machining facility through advanced subtractive manufacturing.

Our highly skilled team ensures technical premium products that meet your exact specifications. Thanks to our fully integrated value chain, we offer short lead times and maximum flexibility. The use of non-fixed tooling components even allows for design changes — right up to the start of production.

Refined to perfection.

To ensure we consistently deliver the highest quality, all incoming raw materials undergo rigorous endurance and performance testing.

Immediately upon arrival, we produce test specimens and examine them thoroughly for key mechanical properties such as elongation at break, tensile strength, and ball indentation hardness.

Only after passing these quality checks with top marks are the materials approved for further processing.