The special features of PCTFE are

- Temperature range from -250°C to +180°C PCTFE shrinks by only 1% when cooled from 23°C to -250°C.

- Non-flammable

- High resistance to creep Comparison of deformation under load of PCTFE to other materials

- Radiation resistance to ionising radiation and hard UV radiation

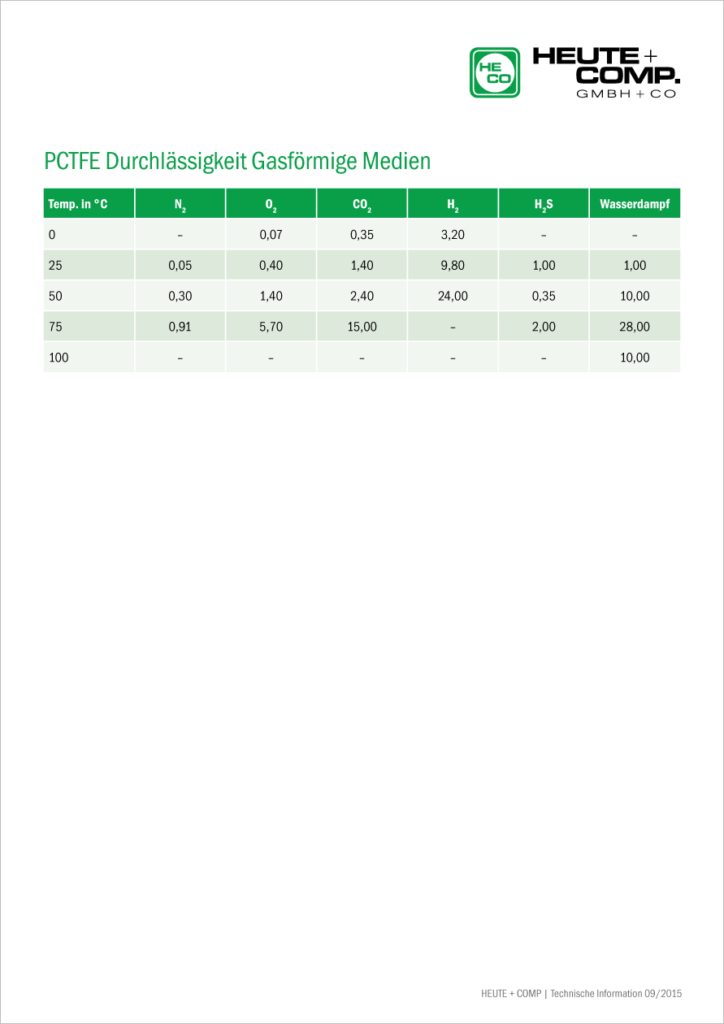

- Low permeability to gaseous and liquid media. See table

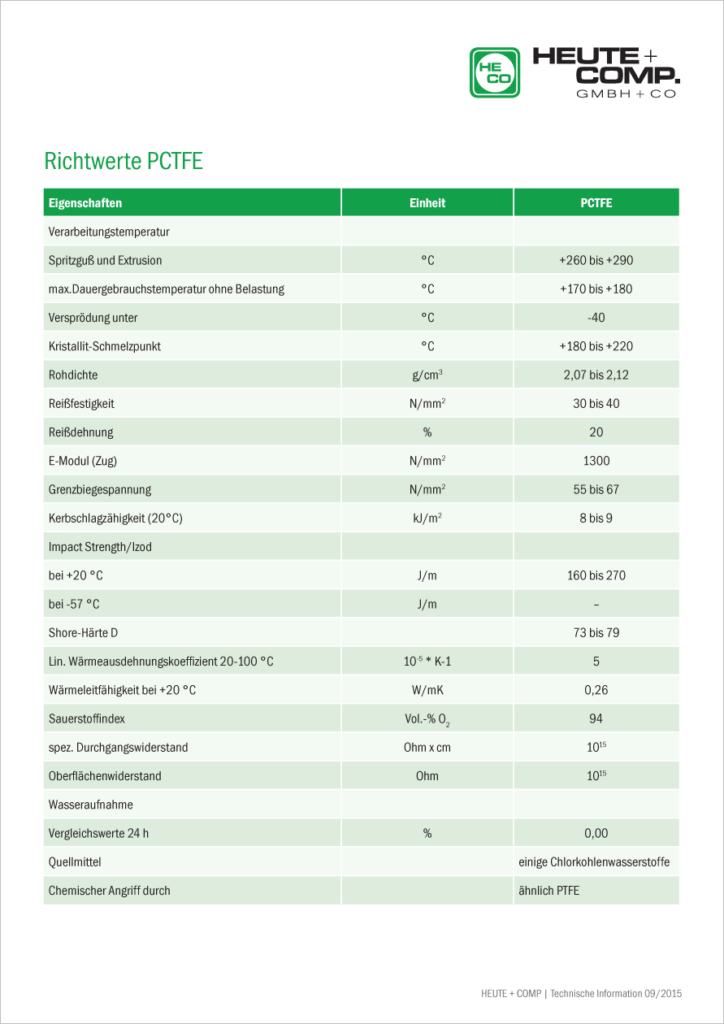

Some mechanical performance values Would you like more information on PCTFE? Request our technical brochure on the subject here.

PCTFE plastic: reinventing an old material with HEUTE+COMP

Modern materials are in greater demand than ever before in all industries. In the automotive industry, electrical engineering and medical technology, we at HEUTE+COMP supply materials such as the durable PCTFE plastic to enable the construction of safe, heat- and cold-resistant parts and to manufacture them ourselves. The more we develop these traditional materials and mould them into suitable parts, the more functional these basic materials become in high-tech production. Discover an old classic in a new guise with polychlorotrifluoroethylene from HEUTE+COMP.

PCTFE has been used in many industrial systems and appliance components for almost 90 years. At that time, it was licensed in the USA as Kel-F 81, among others. Hardly any other plastic is as robust and safe. At HEUTE+COMP, we use PCTFE plastic wherever high and particularly low temperatures play a role.

PCTFE plastic: a material in high demand

With a temperature resistance of up to +180 degrees Celsius down to -250 degrees below zero, this plastic retains its shape. This is made possible by the special composition of the fluoroplastic. At HEUTE+COMP, we have been using this material since the 1960s. Today, we can produce it in its purest, highest quality composition. Our employees are specialists in handling PCTFE plastic and, together with our research department, we are constantly testing new areas of application for the material.

The advantage of in-house research is the willingness to take risks in the production of new parts. Where pure manufacturers can only respond to customer requests within the scope of their usual production, we also supply new, up-and-coming industries. High-tech materials are currently in demand in medical technology, electric vehicle construction and commercial space travel. With our long-established company in Radevormwald, we are competing with international market leaders.

Non-flammable, particularly resistant to radiation: PCTFE in use

When working with plastics, it is particularly important to research their behaviour under extreme climatic conditions. Today, we manufacture precision components that were unthinkable even in science fiction a few decades ago. PCTFE plastic is one of the materials that has been continuously improved since the 1960s for use in sterile and demanding environments such as medical equipment. Among other things, we can utilise the low permeability of gaseous media and resistance to radiation to reinforce casings with PCTFE and improve seals.

It is also particularly important in terms of behaviour at high and low temperatures that the plastic expands as little as possible and shrinks only slightly. Complete resistance to expansion is not achieved with PCTFE plastic, but with only around one per cent change when cooled to 273 degrees, it is almost non-deformable. The high heat resistance is also due to the non-flammability of the material. The bonding molecules only react to the heat above 180 degrees Celsius, but then also deform rather slowly.

HEUTE+COMP: Why are we developing familiar materials further?

At HEUTE+COMP, we have been working with the materials of tomorrow for around sixty years. We have witnessed the first plastic kitchen appliances for private households, computer covers and automotive parts made of plastic and have always been part of the development. Today, we tap into new trends and manufacture semi-finished products such as glass fibres and construction parts for our customers. We work with your company from the first draft to ensure the best possible quality from prototype to series production.

Would you like to plan your next project with durable components made of PCTFE plastic or another robust, durable and versatile plastic? We would be happy to advise you on the costs and planning process for your projects together with our teams, partners and production in our factories. Discover high quality from North Rhine-Westphalia.