In contrast to PTFE, perfluoroalkoxy can be processed thermoplastically.

However, the structure of the molecular chains is similar, so that most of the advantages known from PTFE can also be found in this plastic.

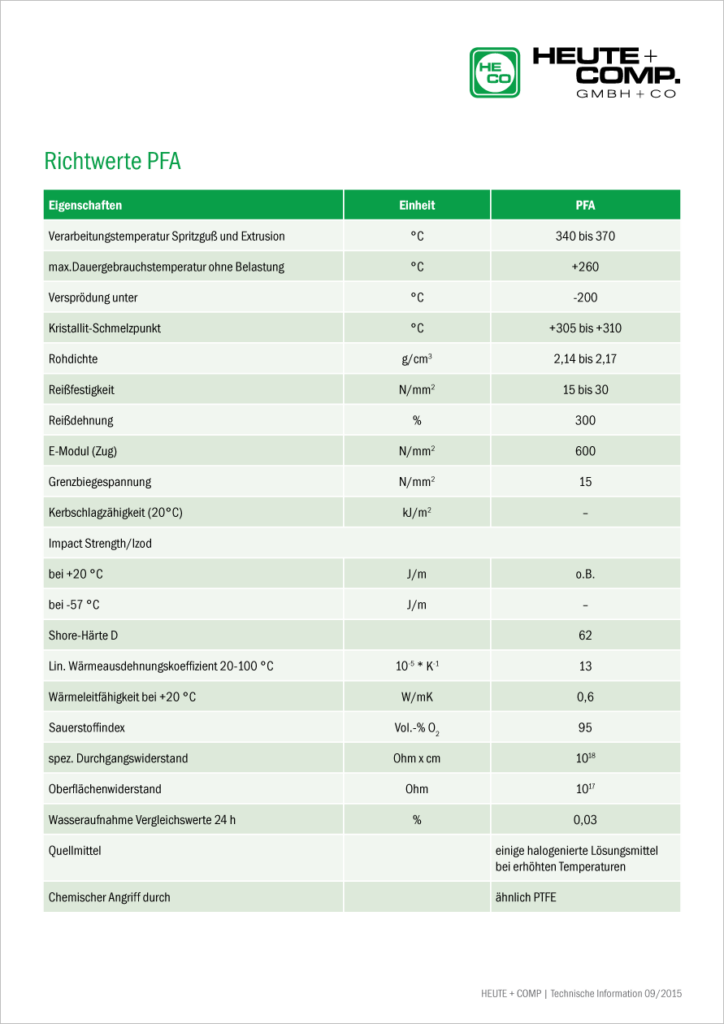

The thermoplastic properties are achieved during the production of the raw material by adding a modifier. PFA is used at HEUTE + COMP. GmbH+Co. mainly for linings and jackets for the chemical industry. The properties of P FA are

- Very good chemical resistance

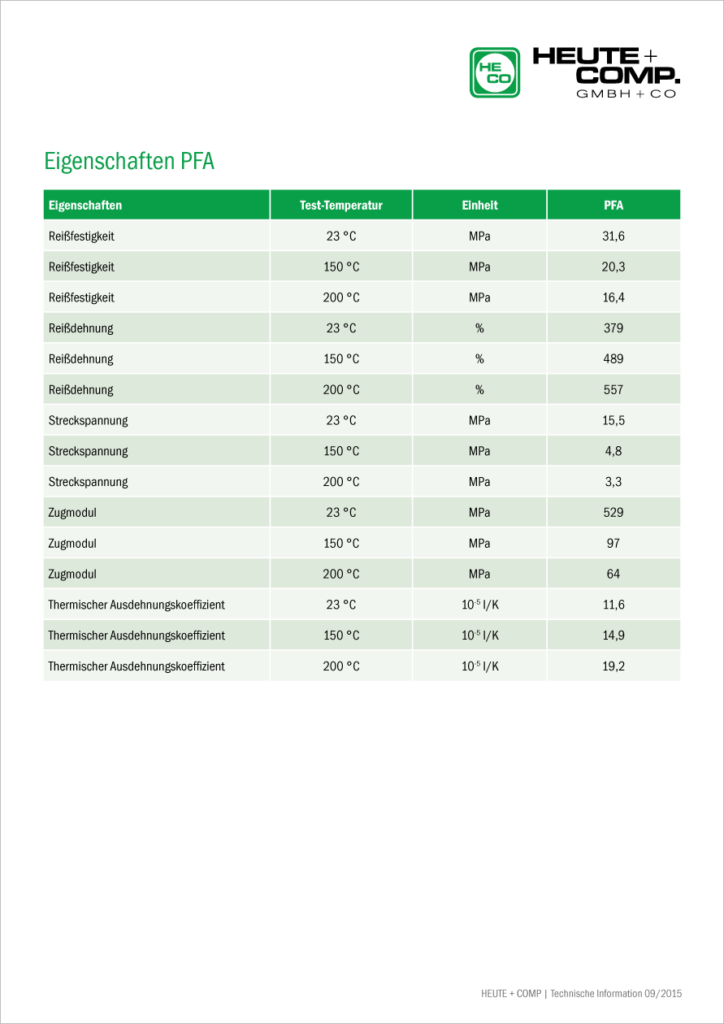

- High temperature resistance Continuous service temperatures from -200°C to +260°C (without mechanical stress) See table

- Excellent sliding properties Easy to clean

- Good insulation behaviour The volume resistivity for PFA, as for PTFE, is 1018 Ohm*cm.

- Water absorption Water absorption is slightly higher than with PTFE and is 0.03% after 24 hours.